Weld Detection

Heavy Machinery

Computer Vision

We developed a reliable computer vision solution for detecting welds on undercarriages and chassis of agricultural machinery. Out system can determine if welds are missing or in the wrong position. By detecting these defects on undercarriages while they were still in their welding fixtures, the time spent on revisions can be cut by 90%.

- Reliable detection of welds on large undercarriages to identify missing or misaligned welds

- Enabled early defect detection while parts were still in welding fixtures, allowing 90% reduction in revision time.

Approach

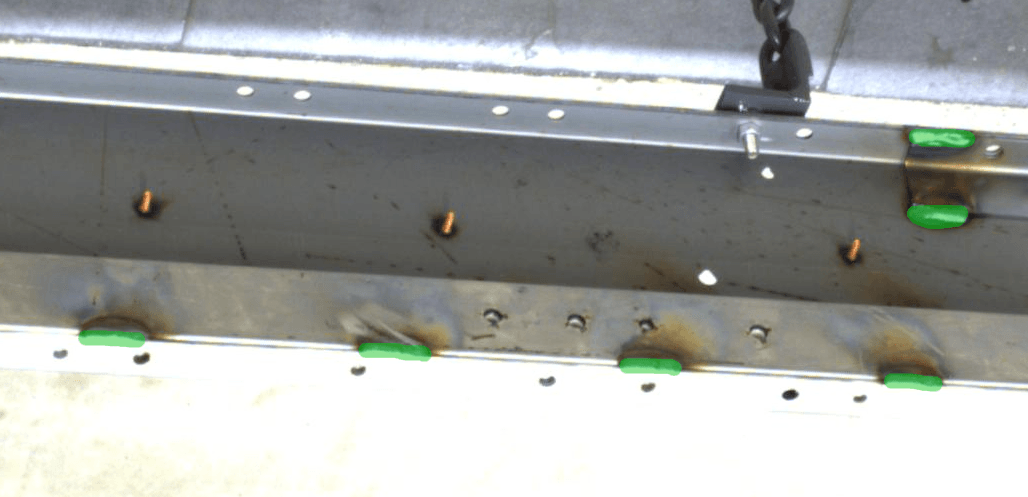

A cloud-based Computer Vision model and industrial-grade cameras next to welding tables enabled detection of missing or misplaced welds on undercarriages before they left the welding fixture, drastically reducing costly rework and delays.

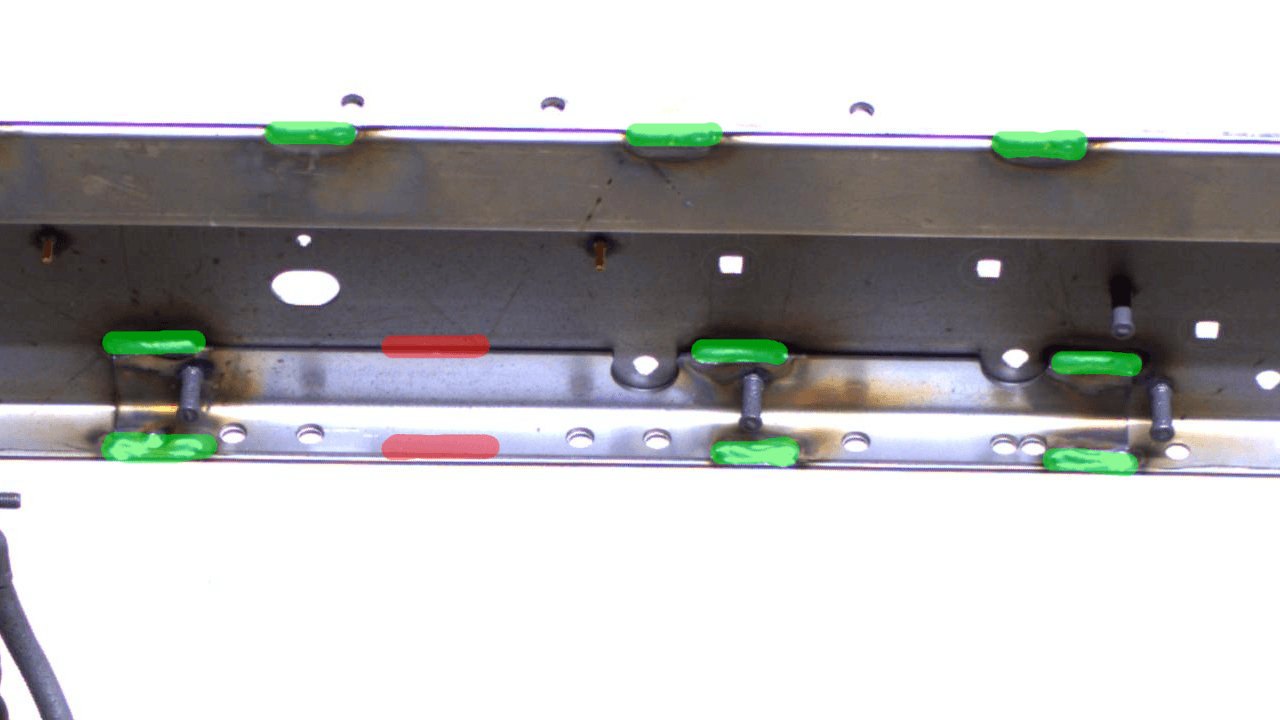

Missing welds on input data marked in red → no match found with the CV algorithm

Computer Vision Solution

- The team trained a Computer Vision model to detect welds in equipment imagery

- We evaluated multiple sensor types to optimize image capture quality

- Synthetic images augmented training data to improve accuracy

- An algorithm compared model predictions to expected ground truth weld positions based on CAD/equipment specifications

Cloud Backend Solution

- We built scalable cloud infrastructure on Azure

- Users interact with a customized UI that also allows monitoring

- Integrated data analytics for performance tracking and insights

- Designed a modular, scalable backend to support future extensions

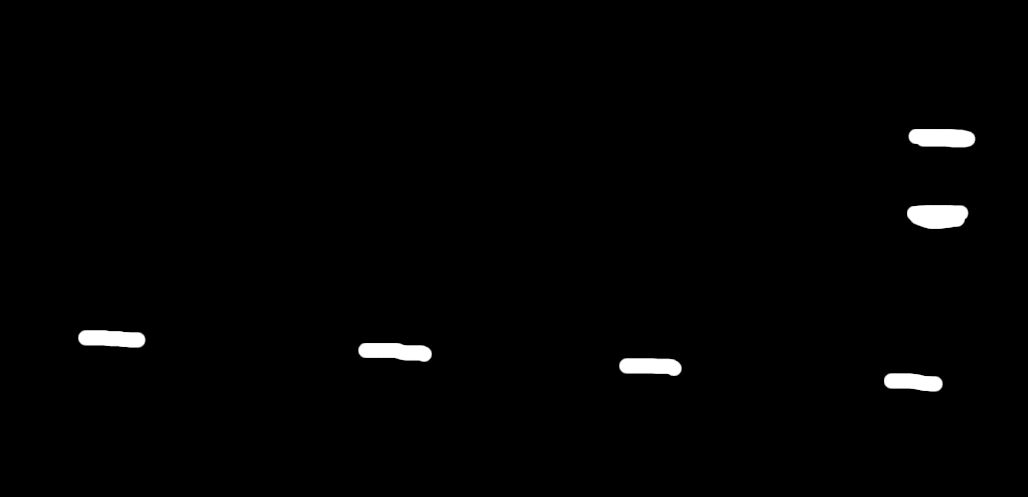

| Original image | Labeling | Ground truth mask |

|---|---|---|

|

|

|

Technologies

- Blender for generating photorealistic synthetic data of possible defects

- YOLO for Computer Vision during development

- Azure AI Vision for production use

Architecture

Application at Schmitz Cargobull

This approach can be applied to various components in the Schmitz Cargobull production line, such as:

- Chassis and undercarriages: Detecting welds on large components

- Welded assemblies: Ensuring completeness of assemblies in complex welded structures

- Increasing automation of QA: Reducing manual inspection effort and increasing reliability